3D UV Laser Marking Machine: The Future of High-Precision Marking

In today's world, where customers demand high-quality products, marking has become an essential aspect of manufacturing. Many industries rely on marking to distinguish their products from their competitors, provide important information, and meet regulatory standards. However, traditional marking techniques like inkjet, dot peen, and engraving have limitations when it comes to marking on challenging surfaces.

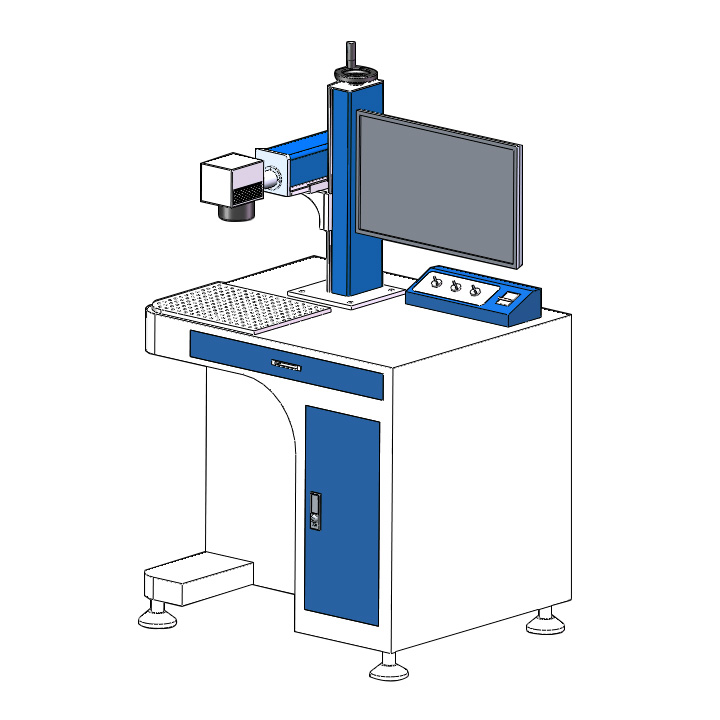

This is where 3D UV laser marking machines come in. The CK-3DUV series of marking machines is the first UV laser marking machine with three-axis control technology. It provides high-precision marking on rugged, circular, and other special-shaped surfaces, widely used in the ultra-fine laser processing of high-end markets.

The CK-3DUV series uses a 355nm wavelength UV laser that can generate a beam width of 0.02-0.06mm, allowing for high-precision marking. The device is equipped with a high-speed galvanometer scanner system that can mark at speeds of up to 7000mm/s. Its three-axis control technology ensures precise positioning and improved marking quality.

One of the biggest advantages of the CK-3DUV series is its ability to mark on a variety of materials, including plastics, ceramics, glass, and metals. This makes it ideal for industries like electronics, aerospace, medical, automotive, and more.

Another advantage of the CK-3DUV series is its user-friendly interface. The device is equipped with a controller that enables easy parameter setting and operation. It also has an automatic focusing system that ensures the correct focal length, making the marking process highly efficient.

In conclusion, the CK-3DUV series of marking machines is a game-changer in the industry. Its high-precision marking capabilities, user-friendly interface, and ability to mark on a variety of surfaces make it an ideal choice for many applications. With Ehao Plastic Group offering high-quality products and excellent services at reasonable prices, customers can benefit from the latest technology and improve their manufacturing processes.